The world moves towards a greener and more sustainable future, electric power train technology has emerged as a crucial player in the transportation industry.

This revolutionary technology replaces traditional internal combustion engines with electric motors, powered by electricity stored in high-capacity battery packs.

The concept of electric vehicles (EVs) is not new, but recent advancements have made them increasingly viable and appealing to consumers. Let's explore the key components and advantages of electric powertrain technology that have made it a driving force behind the push for cleaner and more efficient transportation.

Electric Powertrain Technology

| Component | Description | Common Technologies |

|---|---|---|

| Energy Storage | Stores electrical energy to power the vehicle. | Lithium-ion batteries, Nickel-metal hydride batteries, Supercapacitors |

| Electric Motor | Converts electrical energy into mechanical energy to drive the wheels. | Permanent magnet synchronous motor (PMSM), Induction motor, Synchronous reluctance motor |

| Power Electronics | Controls the flow of electrical energy between the battery and motor. | Inverters, DC-DC converters |

| Transmission | Transfers mechanical energy from the motor to the wheels. | Single-speed or multi-speed gearboxes, Direct drive |

| Charging System | Replenishes the battery's energy. | AC charging, DC charging, Wireless charging |

| Regenerative Braking | Reclaims kinetic energy during braking and stores it in the battery. | Electrical braking system |

Key Considerations:

- Efficiency: The overall efficiency of the electric powertrain is crucial for maximizing range and minimizing energy consumption.

- Weight and Size: The weight and size of components can impact vehicle performance and design.

- Cost: The cost of materials, manufacturing, and maintenance can affect the overall cost of the electric vehicle.

- Performance: The power output, torque, and acceleration of the electric powertrain are important factors for driving experience.

- Reliability: The reliability and durability of components are essential for long-term vehicle operation.

Future Trends:

- Solid-state batteries: Offering higher energy density and improved safety.

- Advanced motor technologies: Increasing efficiency and power output.

- Wireless charging infrastructure: Simplifying the charging process.

- Integration with renewable energy sources: Reducing reliance on fossil fuels.

Components of Electric Powertrain Technology

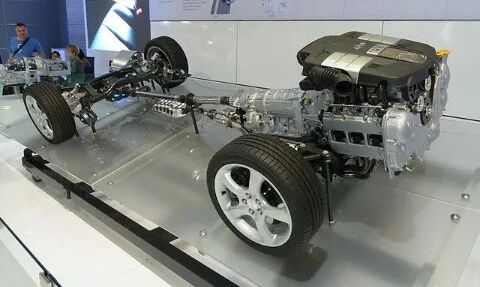

Electric powertrains consist of several key components working in harmony to propel the vehicle.

These components include:

1. Electric Motor: At the heart of the electric powertrain is the electric motor. Unlike the complex combustion process in conventional engines, electric motors generate motion by leveraging the magnetic fields created by electric currents flowing through coils.

This simple yet highly efficient process results in instant torque delivery, providing smooth and silent acceleration.

2. Battery Pack: Electric vehicles utilize advanced lithium-ion battery packs to store electrical energy. These battery packs are made up of numerous individual battery cells connected in series and parallel configurations to achieve the desired capacity and voltage.

The continuous improvements in battery technology have led to higher energy densities, longer driving ranges, and reduced charging times.

3. Power Electronics: Power electronics play a vital role in managing the flow of electrical energy between the battery and the electric motor.

This includes components like inverters, converters, and controllers, which convert DC power from the battery to AC power for the motor, ensuring precise control over the motor's speed and torque.

4. Charging System: Electric powertrain technology requires a charging system to replenish the energy stored in the battery. Charging options range from standard Level 1 charging using a regular household outlet to faster Level 2 charging using specialized charging stations.

Additionally, DC fast-charging stations are available for rapid charging during long-distance travel.

Advantages of Electric Powertrain Technology

The widespread adoption of electric powertrain technology offers numerous advantages that contribute to a more sustainable and efficient transportation ecosystem:

1. Zero Emissions: Electric vehicles produce zero tailpipe emissions, reducing greenhouse gas emissions and air pollution, which are major contributors to climate change and health issues.

2. Energy Efficiency: Electric powertrains are inherently more energy-efficient than internal combustion engines. Electric motors convert a higher percentage of the stored energy into usable mechanical power, resulting in reduced energy waste.

3. Silent Operation: The absence of engine noise makes electric vehicles remarkably quiet, contributing to reduced noise pollution in urban areas.

4. Lower Operating Costs: Electric vehicles have lower operating costs compared to traditional internal combustion engine vehicles. Electricity is generally cheaper than gasoline or diesel fuel, and EVs have fewer moving parts, reducing maintenance requirements.

5. Regenerative Braking: Electric powertrains utilize regenerative braking technology, which recaptures energy during deceleration and braking, converting it back into electricity and recharging the battery. This feature enhances energy efficiency and extends driving range.

Electric powertrain manufacture

Electric powertrain manufacture involves the production of key components and systems that constitute the heart of electric vehicles (EVs).

The process encompasses the creation of electric motors, battery packs, power electronics, and associated components that work in unison to drive and power the vehicle. Manufacturers of electric powertrains typically employ advanced engineering, cutting-edge technologies, and stringent quality control measures to ensure the reliability, performance, and safety of these components.

1. Electric Motors: Electric motor manufacturing involves the precise assembly of stator and rotor components, which generate the rotational motion required to drive the wheels of the EV. Manufacturers focus on designing efficient and powerful motors, using high-quality materials and specialized manufacturing techniques to achieve optimal performance and energy efficiency.

2. Battery Pack Assembly: The production of battery packs is a critical aspect of electric powertrain manufacture. Battery cells, typically lithium-ion, are carefully integrated into modules, and multiple modules are then interconnected to create a complete battery pack.

Stringent safety protocols are followed during assembly, and manufacturers pay close attention to thermal management to ensure the battery's longevity and performance.

3. Power Electronics: The manufacturing of power electronics involves the production of inverters, converters, and controllers that manage the flow of electrical energy between the battery and the electric motor.

These components are vital for converting DC power from the battery to AC power for the motor, as well as controlling the motor's speed and torque accurately.

4. Charging System Components: Electric powertrain manufacturers also produce charging system components, including onboard chargers and charging connectors.

These components allow the EV to be charged from various power sources, such as standard household outlets, Level 2 charging stations, and high-power DC fast-charging stations.

Manufacturers of electric powertrains often work closely with automakers or other companies in the electric vehicle industry to integrate these components seamlessly into the final product. Collaboration with battery manufacturers, software developers, and design teams is essential to ensure optimal performance, safety, and efficiency of the electric powertrain.

As the demand for electric vehicles continues to grow, electric powertrain manufacturers invest in research and development to advance technology, improve energy efficiency, and reduce production costs.

The ongoing evolution of electric powertrain manufacturing plays a pivotal role in driving the global transition to cleaner and more sustainable transportation solutions.

Conclusion Electric Powertrain Technology

Electric powertrain technology represents a significant leap forward in the quest for sustainable and environmentally friendly transportation.

As advancements continue, electric vehicles are becoming more accessible, affordable, and practical for everyday use. The shift towards electric mobility has the potential to revolutionize the automotive industry, reduce our carbon footprint, and pave the way towards a cleaner and greener future.

Embracing electric powertrain technology is not just a trend but a crucial step towards building a more sustainable world for generations to come.